Injection Molding

We’re your best one-stop-shop if you need injection molding service for your plastic parts. Here at Proto Expedited, we can make high quality rapid tooling with aluminum molds as fast as 2 weeks and production molds as fast as 4 weeks.

Whether you need rapid tooling, full-scale production mold with tight tolerances, our experienced engineering team can offer professional and valuable suggestions and solutions from prototype to production stage.

High Quality

Fast Lead Time

Competitive Pricing

Precision Parts

What is Injection Moulding?

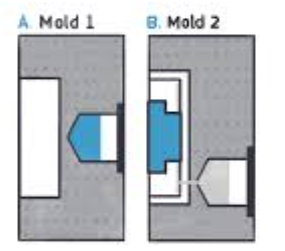

Injection molding is a manufacturing process that inject plastic into a metal mold. The parts subsequently cool and are ejected from the mold cavity using pins. Some features like undercuts can also be easily made by using sliding cores.

Injection molding is the best choice for high volume production of plastic parts. We also offer vacuum casting service if you need lower quantity production.

Our Advantages:

Family Mold

High-Volume Production

Affordability

High Tensile Strength

Multi-Cavity Mold

T1 Sample in 4 Weeks

Rapid Tooling

Production Tooling

Overmolding

Why Injection Molding With Proto Expedited

| Thermoplastics |

| ABS |

| HIPS |

| Nylon (PA) |

| Glass Filled Nylon (PA%GF…) |

| PC |

| PE/HDPE/LDPE |

| PEEK |

| PET |

| PMMA |

| POM |

| PP |

| PVC |

| TPU |

Available Materials for Injection Molding

Please contact sales@protoexpedited.com if the materials you need are not listed.